HSR turbocompressor

The HSR turbocompressor is highly suitable for providing -pulp, paper and board

-Food and Beverage

-Chemical Processing

-Pharmaceutical and Medical

-Electronics Manufacturing

-Textile Manufacturing

The HSR turbocompressor is highly suitable for providing -pulp, paper and board

-Food and Beverage

-Chemical Processing

-Pharmaceutical and Medical

-Electronics Manufacturing

-Textile Manufacturing

Features and benefits

-Totally oil free

-High overall efficiency

-Magnetic bearings

-Compact package

-Superior capacity control

-Heat recovery built in

-Lowest cost of maintenance

-Totally oil free

-High overall efficiency

-Magnetic bearings

-Compact package

-Superior capacity control

-Heat recovery built in

-Lowest cost of maintenance

High-speed technology

-Minimum number of moving parts

-No contact, no wear

-Real-time monitoring built in

-Vibration-free

-No oil whatsoever

-Motor efficiency through design

-From the originator of high-speed technology

-Minimum number of moving parts

-No contact, no wear

-Real-time monitoring built in

-Vibration-free

-No oil whatsoever

-Motor efficiency through design

-From the originator of high-speed technology

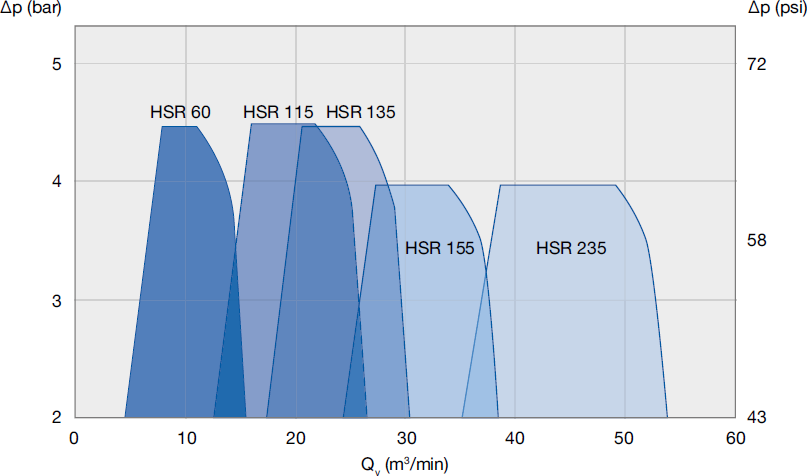

Operating data 2-stage

Pressure 2 - 5 bar (g)

Volume flow max. 52 m³/min

Input power 60 - 235 kW

Input voltage 380 - 500 V

Input frequency 50 - 60 Hz

Protection IP33D

Max. noise level 80 dB

Pressure 2 - 5 bar (g)

Volume flow max. 52 m³/min

Input power 60 - 235 kW

Input voltage 380 - 500 V

Input frequency 50 - 60 Hz

Protection IP33D

Max. noise level 80 dB

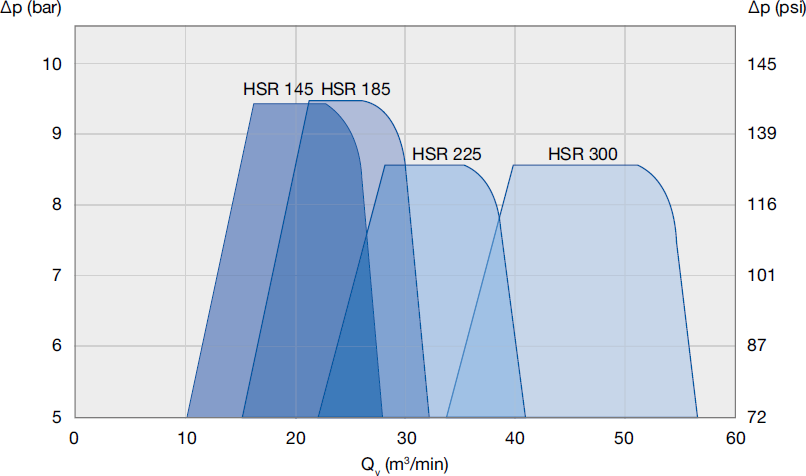

Operating data 3-stage

Pressure 5 - 9 bar (g)

Volume flow max. 56 m3/min

Input power 145 - 300 kW

Input voltage 380 - 500 V

Input frequency 50 - 60 Hz

Protection IP33D

Max. noise level 80 dB

Pressure 5 - 9 bar (g)

Volume flow max. 56 m3/min

Input power 145 - 300 kW

Input voltage 380 - 500 V

Input frequency 50 - 60 Hz

Protection IP33D

Max. noise level 80 dB